Thanks to Carl Johnson from Minneapolis, Minnesota for sending in this Anarchist’s Roubo Workbench featuring a wooden leg vise. Built mainly out of southern yellow pine, with a hard maple vise chop, Carl did quite the amazing job on this bench.

Here, at long last, is my new workbench. I built it according to the plans in the wonderful book, “The Anarchist’s Workbench” by Christopher Schwarz. I built it according to the plans almost verbatim. The only thing I altered was the overall length and opted for a wooden vise screw and parallel guide for the leg vise.

This bench has been my mistress for the last two months. I have only been woodworking for about a year and a half, and although I’ve built many different kinds of projects, this bench pushed me to a new level. Virtually every technique was new to me. This bench was my first stab at mortise and tenon joints, my first time ever using hand tools, and was also a great excuse to buy some new toys and tools!

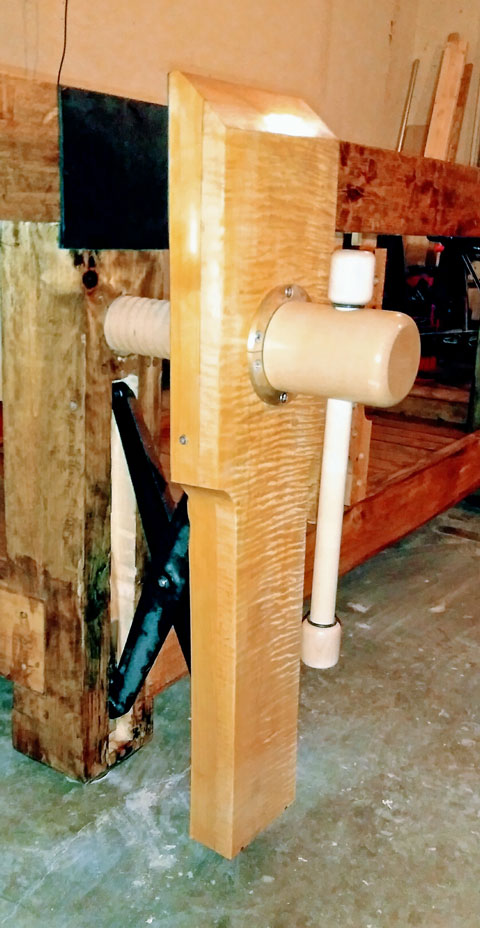

It is built entirely from southern yellow pine, except for the leg vise which is hard maple with curly maple on the face. I started out with eight 2x12x12 boards and cut them all to rough length before planing them down to 1 ¼” and ripping them to width (this gave me a great excuse to buy a rip blade for the table saw).

The top is 5” thick, around 5 ½’ in length and 22” for width. I opted for a 35” height, so we’ll see how I like that height when hand planing. As per the book, I bought some architect’s lamps for lighting. I made bases for them out of canary wood and pau rosa, which I turned on a lathe to make into thick hockey pucks. I cut a hole in the top of the base for the lamp to slide into, then attached a 1” dowel through the underside so the bases can sit in the holdfast holes.

As I mentioned before, I opted for wooden vise hardware over steel because I just loved the look. I briefly considered making my own wooden screw and nut out of hard maple, but decided it wasn’t worth the time hassle at this point in my woodworking journey. Enter Lake Erie Toolworks. I bought the premium kit, and was not disappointed. All the components are made from single pieces of hard maple and they’re absolutely beautiful. And boy does this thing clamp hard!

The rest of the bench I finished with a 1:1:1 mix of boiled linseed oil, polyurethane and paint thinner. This bench has been a labor of love, and by far the lengthiest project I’ve undertaken. It’s hard to believe it’s done, because for so long there was always something to do next. I’m still waiting on a planing stop, though (the popularity of the book probably resulted in a deluge of orders to the blacksmith that Chris mentions in the book).

The whole reason for building this bench was to have something I can use to build staked furniture, so those are going to be my next projects. Though, I think I may take a breather for a while…

Carl Johnson – Minneapolis, Minnesota